From Empty Space to Grand Opening:

A Complete, Real-World Construction Timeline for Building a Laundromat

A modern laundromat looks deceptively simple. Stainless-steel machines line the walls. Bright lighting creates a clean, predictable environment. Customers arrive, load clothes, and leave with freshly folded laundry.

What customers never see is the industrial-scale infrastructure hiding beneath the floor and above the ceiling. A laundromat is not a typical retail space—it is a tightly engineered utility system that happens to be open to the public. Water volume, sewer slope, gas pressure, electrical amperage, ventilation, and equipment sequencing drive nearly every design and construction decision.

This article provides a comprehensive, real-world look at how laundromats are actually built. It follows the full lifecycle—from site selection and financing through final inspections—using a realistic 20–30 week timeline and a representative $1.2 million project budget.

Abstract

Building a laundromat is often misunderstood as a straightforward retail construction project. In reality, it is an infrastructure-heavy undertaking shaped less by aesthetics than by utilities, sequencing, and municipal coordination. Water volume, sewer capacity, gas pressure, electrical load, and ventilation requirements dictate nearly every decision—from site selection and equipment mix to construction phasing and inspection timing.

This article provides a comprehensive, real-world overview of the laundromat development process, tracing the journey from early location analysis and financing through design, permitting, construction, equipment installation, and opening. Using a realistic 20–30 week timeline and a representative $1.2 million build budget, it illustrates how capital is deployed, where delays most commonly occur, and why underground work and utility coordination form the project’s critical path. The result is a practical framework for understanding laundromats not as simple retail spaces, but as durable, utility-driven businesses built to operate reliably for decades.

Why Laundromats Are Fundamentally Different from Retail Buildouts

Most commercial tenants approach construction as an architectural exercise: walls, lighting, finishes, signage. For laundromats, architecture is secondary. Utilities are the primary constraint.

A mid-sized laundromat can require hundreds of gallons of water per hour, large-diameter sewer lines with precise slope, gas demand comparable to a restaurant or light manufacturing facility, and electrical service ranging from 400 to more than 1,200 amps. These requirements often exceed what an existing retail space can provide.

Because utilities are embedded into concrete slabs and structural systems, mistakes made early are not cosmetic—they are permanent. Correcting them later can require re-trenching floors, replacing panels, or delaying opening by months.

Before Construction: Location, Demographics, and Capital Strategy

Construction timelines are shaped long before permits are submitted. Site selection determines not only customer demand but also construction complexity.

Older buildings may offer lower rent but insufficient sewer capacity. Newer spaces may have strong utilities but restrictive municipal processes. Population density, renter concentration, average household size, and competition density all influence the appropriate equipment mix—and therefore the utility load.

In parallel, financing must be structured to absorb uncertainty. Even well-managed projects encounter delays caused by permitting backlogs or utility upgrades. A realistic capital stack includes contingency funding and interest reserves that align with the construction schedule.

“Laundromats Are Built on Utilities, Not Walls”

The Big Picture Timeline: What 20–30 Weeks Really Looks Like

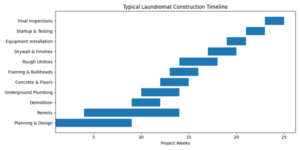

Most laundromats open between 20 and 30 weeks after lease execution. This range reflects differences in municipal responsiveness, utility readiness, and project scale.

Critically, not all weeks are equal. Some phases overlap naturally, while others form a strict critical path. Underground plumbing and concrete work, for example, cannot be rushed without compromising inspections.

Understanding where flexibility exists—and where it does not—is essential for managing expectations.

Figure 1: A representative laundromat construction timeline. Planning and permitting overlap with early demolition, while underground plumbing and concrete define a critical path that cannot be compressed without risk.

Phase One: Planning and Engineering (Weeks 1–8)

Planning is where laundromat projects are either de-risked or quietly set up for failure.

During this phase, architects and engineers translate an equipment mix into physical reality. This includes washer spacing, trench layouts, drain sizing, gas demand calculations, electrical load analysis, HVAC design, and ADA compliance.

The goal is not aesthetic perfection, but constructability. Every decision should reduce ambiguity before concrete is cut.

Permitting and Utility Coordination (Weeks 4–14)

Permitting often overlaps with planning and early construction, but it remains the single most unpredictable element of the schedule.

Building, plumbing, electrical, mechanical, fire, and health departments may all require review. Separately, water, sewer, gas, and electrical utilities must approve service upgrades.

Because these entities operate on their own timelines, early submission and proactive follow-up are critical.

Demolition, Trenching, and the Point of No Return

Once demolition begins, the project enters irreversible territory. Existing floors are removed, slabs are exposed, and trenching begins.

Underground plumbing is the most consequential phase of the entire build. Drain placement, slope, and cleanout access must be correct before concrete is replaced. Mistakes discovered later are expensive and disruptive.

“In laundromats, concrete and pipe matter more than paint.”

Concrete, Framing, and Building the Hidden Structure

After plumbing inspections, trenches are backfilled and concrete is poured. Curing time is not optional—installing heavy equipment too early can compromise the slab.

Framing and bulkheads follow, shaping ceiling heights and concealing ductwork, plumbing runs, and electrical conduits. These elements are functional as much as visual.

“Equipment decisions dictate construction, not the other way around.”

Rough Utilities: Plumbing, Electrical, and Mechanical Systems

Rough-in work brings the laundromat’s infrastructure to life. Water, gas, electrical, exhaust, and make-up air systems are installed and inspected.

This phase determines long-term reliability. Undersized systems or rushed installations often result in chronic operational issues after opening.

Interior Finishes and the Transition to Customer Space

Drywall, ceilings, lighting, flooring, and paint transform the project from construction site to consumer environment.

Finishes are often where owners focus attention, but they should never compromise access to mechanical systems or serviceability.

“Retail on the surface. Infrastructure underneath.”

Equipment Installation, Startup, and Final Inspections

Equipment installation begins only after floors are finished and utilities are ready. Washers are anchored, dryers stacked, and support equipment installed.

Final utility connections, testing, and programming lead to inspections and issuance of a Certificate of Occupancy. Only then can the business legally open.

Figure 2: Step-by-step utility flow in a laundromat. Municipal services first pass through meters and shutoffs controlled by the utility provider. From there, utilities enter the building’s internal distribution systems such as electrical panels and gas manifolds. Mechanical systems—including water heaters, boilers, and pressure boosters—condition and regulate utilities before they reach washers and dryers. Each transition point represents a permitting, inspection, and capacity checkpoint that can affect construction timelines.

“In laundromats, cash flow starts in the planning phase.”

Understanding the $1.2 Million Capital Deployment

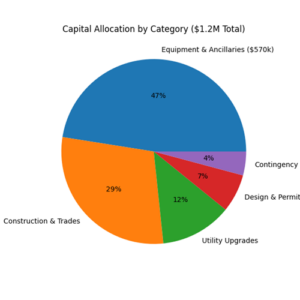

A representative modern laundromat build totals approximately $1.2 million.

About $570,000 is allocated to equipment and equipment-related infrastructure. This includes washers, dryers, bulkheads, carts, furniture, drain troughs, and ancillary systems required for operation.

The remaining capital funds construction labor, utility upgrades, professional fees, permitting, and contingency.

Figure 3: Capital allocation for a representative $1.2 million laundromat project. Nearly half of total capital is tied directly to revenue-generating equipment and required ancillaries.

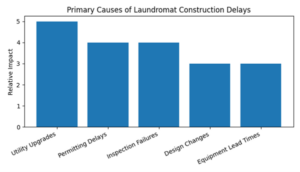

Figure 4: The most common causes of laundromat construction delays. Utility coordination and permitting consistently represent the highest risk.

Why Sequencing Determines Long-Term Success

Laundromat construction does not reward haste. It rewards discipline.

Projects that succeed respect sequencing, coordinate early with utilities, and lock equipment decisions before trenching begins. The payoff is a durable, infrastructure-backed business capable of operating reliably for decades.

Conclusion

Laundromats succeed or fail long before the first customer loads a washer. The outcome is determined by decisions made during planning, by how well utilities are understood and coordinated, and by whether construction sequencing is respected rather than rushed.

Unlike conventional retail projects, laundromat buildouts are governed by physical constraints that cannot be negotiated away. Sewer lines must slope correctly. Concrete must cure. Gas pressure must meet demand. Electrical service must be sized not just for today’s load, but for years of continuous operation. These realities explain why permitting, inspections, and utility upgrades so often control the schedule—and why attempts to shortcut them usually backfire.

The projects that reach opening on time and on budget are not the fastest, but the most disciplined. They lock equipment decisions early, coordinate proactively with municipalities and utility providers, and treat underground work as the point of no return that it truly is. When executed with this mindset, a laundromat becomes more than a storefront—it becomes a resilient, infrastructure-backed asset capable of delivering predictable service and cash flow for decades.

“Build the system, then the space.”

Executive Takeaway

Laundromat construction is best understood not as a retail buildout, but as an infrastructure project constrained by utilities, sequencing, and municipal coordination. Projects that succeed do so by locking equipment decisions early, sizing water, sewer, gas, and electrical systems conservatively, and respecting the non-negotiable critical path created by underground plumbing, concrete, and inspections. While a typical build may span 20–30 weeks and require approximately $1.2 million in capital—nearly half of which is tied to equipment and required ancillaries—the true determinant of success is not speed, but discipline. Developers who plan for utility complexity, permit variability, and realistic timelines are far more likely to deliver a durable, cash-flowing asset that operates reliably for decades.